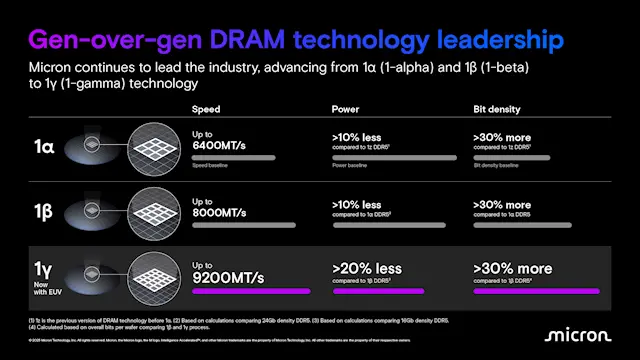

Fast Technology reported on February 26 that Micron announced that DDR5 DRAM memory chips based on the latest 1γnm process have been put into production, and various indicators such as performance, energy efficiency, and density have been greatly improved.

The node process in the DRAM memory industry has not been marked with specific values, but the iterative sequence of 1a, 1b, 1c, 1α, 1β, and 1γ is becoming more and more advanced, of which 1a is closer to 20nm and 1γ is closer to 10nm.

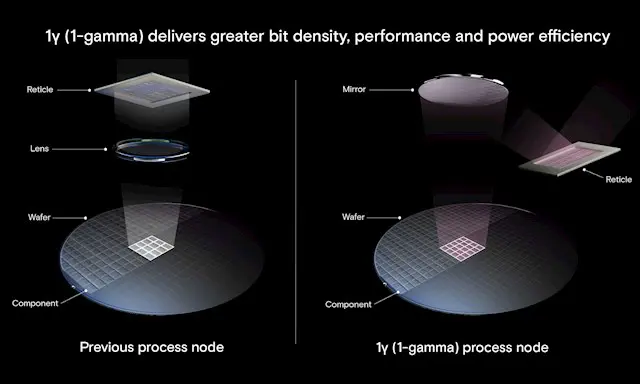

This is the first time that Micron memory has used EUV extreme ultraviolet lithography process, and Samsung and SK hynix have long used it, but Micron has also introduced the next generation of HKMG metal gate technology this time, and it is expected that the new BEOL back-end process will be used.

However, Micron did not disclose how many EUV lithography layers are used, speculating that EUV is currently only used on key layers, otherwise it will have to be reexposed, increasing time and cost.

Micron’s 1γ DDR5 has a single capacity of 16Gb (2GB), which can easily form a single 128GB enterprise-class product, claiming that the capacity density is 30% higher than that of 1β, in fact, each previous generation of lifting process can increase the density by 30%.

It only needs a standard voltage of 1.1V to reach an ultra-high frequency of 9200MHz (strictly speaking, 9200MT/s), while the common high-frequency memory on the market often has a high voltage of 1.35V or even 1.45V.

Lower voltages are not only safer, but also save power consumption, which is claimed to be up to 20% lower than the 1β process.

At present, Micron’s 1γ DDR5 memory is only produced in the Japanese factory, and the production capacity will be gradually expanded in the future, and related products are expected to be launched around the middle of this year.

In the future, Micron’s factory in Taiwan will also introduce EVUs and use the 1γ process to manufacture GDDR7 video memory and LPDDR 5X high-frequency memory (up to 9600MHz).

Entering China

Entering China